Our BASELINE portfolio includes single panels for centralized supply of gases with purities up to 5.0 grade and gas mixtures with components at % level. They reduce the high primary pressure at the source to the required secondary pressure at the point of use.

Read on for more details on individual models.

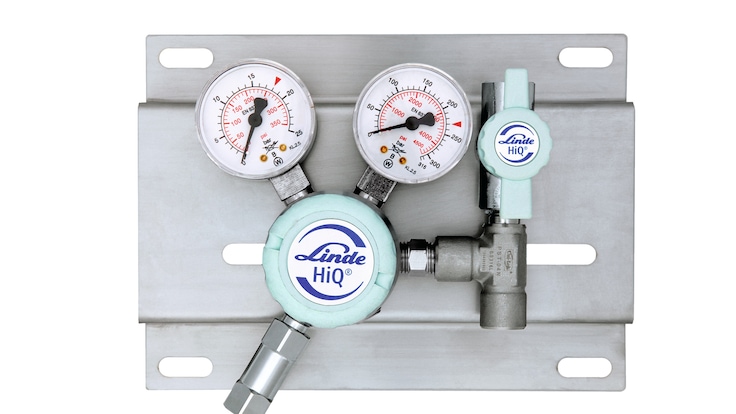

BASELINE® S 100

The S 100 manual gas panel is designed to handle a single bank with cylinders or bundles containing compressed or condensed gases. It is mounted on a stainless steel console and consists of a pressure regulator, inlet and outlet pressure gauges and a relief valve. If required, the panel can be equipped with an inductive contact gauge. Inlet and outlet shut-off valves or check valves can be mounted. The maximum primary pressure is 230 bar (3,336 psi) and the outlet pressure ranges from 2.5 bar (36 psi) to 14 bar (203 psi).

BASELINE® S 101

The S 101 manual gas panel is suited to a single bank with cylinders or bundles containing compressed or condensed gases. The panel is equipped with internal gas purging to avoid contaminants entering the process line after a cylinder changeout. It is mounted on a stainless steel console and consists of a pressure regulator, inlet and outlet gauges and a relief valve. The panel can be equipped with inductive contact gauges for automatic monitoring. If required, inlet and outlet shut-off valves or check valves are available. The maximum primary pressure is 220 bar (3,336 psi) and the outlet pressure range goes from 2.5 bar (36 psi) to 14 bar (203 psi).