Scale your freezing capacity as you grow with our modular CRYOLINE® TI, CRYOLINE® SC and CRYOLINE® MT linear freezer models

Over the decades, we have developed an exceptionally broad lineup of cryogenic freezers to meet the highly varied and constantly evolving needs of the food processing industry. Our CRYOLINE® range uses the rapid cooling power of liquid nitrogen (LIN) or carbon dioxide (LIC) to quickly and gently remove heat from a variety of food products. Our modern freezers can be installed quickly and easily, combining the latest smart control capabilities to increase efficiency with maintenance-friendly designs that meet the stringent hygiene standards.

Benefits of our CRYOLINE Freezers at a Glance:

Cryogenic freezing and cooling of foodstuffs using liquid nitrogen or carbon dioxide is a well established technology that has been enhancing food processing for many decades. Cryogenic gases offer a number of benefits over mechanical freezers. These are summarized in the following:

Click on the links below to see which linear, batch or IQF model would work best for you.

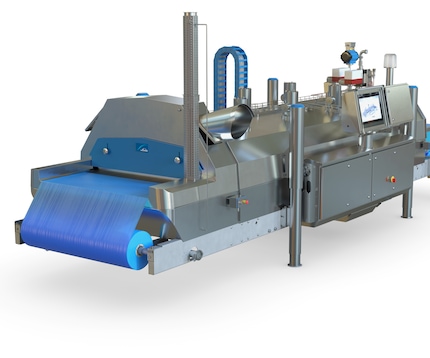

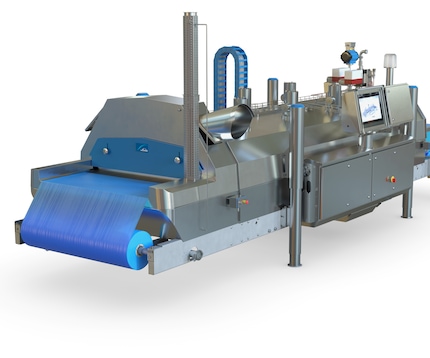

Scale your freezing capacity as you grow with our modular CRYOLINE® TI, CRYOLINE® SC and CRYOLINE® MT linear freezer models

Select the model that best suits your individually quick frozen foodstuffs from our lineup spanning CRYOLINE® CW, CRYOLINE® CWI and CRYOLINE® UPF and more

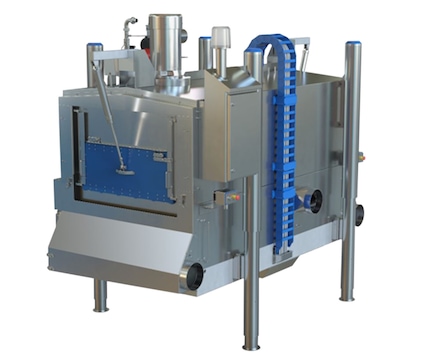

Lock in flavor and reduce dehydration with the on-demand power of our CRYOLINE® freezers for batch and food service production lines

Pack big cooling power into a small footprint with our spiral models including CRYOLINE® CS, CRYOLINE® CX and CRYOLINE® UPS

Scale your cooling capacity as you go - with our flexible, compact range of boosting solutions designed to complement or expand existing assets

Increase productivity and quality quickly and cost-effectively - with our dedicated freezing solutions for a rapid, uniform crust freeze

Take the challenge out of difficult-to-process products with special-purpose solutions that increase portioning accuracy, ease of handling and sanitation