How Does It Work?

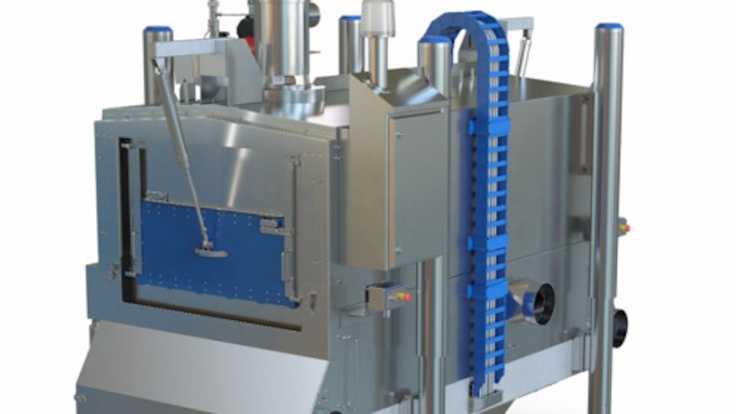

The CRYOLINE RC is a specialized semi-batch freezer designed to provide consistent crust-frozen product for high-capacity slicing lines. It delivers a high-velocity stream of liquid nitrogen (LIN) in an innovative gas flow pattern to rapidly remove heat from the product surface and form the frozen crust. This fast heat transfer enables a small footprint, a short dwell time and highly efficient freezing. In addition to a uniform crust around the perimeter, this gas delivery pattern optimizes cryogen use. The control handshake for upstream and downstream processes further boosts productivity.

This freezer is the ideal choice for food processors looking to increase slicing yield or overcome the challenges and cost associated with improper crust formation or tempering. The CRYOLINE RC is best suited to slicing operations of ham, sausage, cooked meats, bacon, raw cuts and plant-based products.

Benefits at a Glance

- Increased

slicing yield

Rapid heat transfer on a small footprint - Innovative

gas flow

Accelerating heat transfer rate of general-use tunnel freezers by up to 300% - Just-in-time

crust freezing before each slicer

Consistent, high-quality batch-to-batch crust characteristics - Adaptability

Tunable crust for different products

Efficiency Optimized cryogen use and semi-batch product handling - Labor

savings

Reduced manual product handling plus control handshake for upstream and downstream processes - Hygienic

design

Ease of access with sloped and rounded surfaces for best sanitation