Gas Based Applications for Pulp & Papermaking

Innovating with Customers for Process Improvements

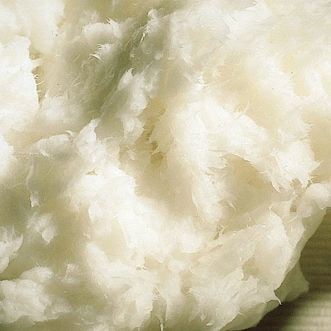

Helping to Make Pulp & Papermaking More Productive, Environmentally Friendly and Cost-effective

As a reliable, trusted expert, we have been helping pulp and papermakers to improve their processes for many decades.

Building on our experience, we explore ways our application toolbox can help solve our customers' challenges. These tools include ACTICO™ CO2 pulp wash, used to improve brownstock washing. The potential benefits of this solution include a reduction in soda loss, often sufficient to generate fast return on investment. Another tool is ACTICO™ pH control, which can be used when there has been no previous control method through to replacing dangerous acids, often also outperforming them.

Building on our experience, we explore ways our application toolbox can help solve our customers' challenges. These tools include ACTICO™ CO2 pulp wash, used to improve brownstock washing. The potential benefits of this solution include a reduction in soda loss, often sufficient to generate fast return on investment. Another tool is ACTICO™ pH control, which can be used when there has been no previous control method through to replacing dangerous acids, often also outperforming them.

Unlocking Efficiency Gains with ACTICO CO2 Pulp Wash

Our innovative and field-proven ACTICO™ CO2 pulp wash improves brownstock washing of kraft pulp, which may be subsequently bleached or not. Especially in the case of high kappa pulps, the addition of carbon dioxide (CO2) during washing offers significant benefits. New mills normally incorporate this application at the design phase. Older mills can benefit from an update, which not only reduces carry-over and defoamer consumption, but can also increase washer capacity and reduce wash water consumption.

Environmental and Efficiency Improvements with ACTICO pH Control

Carbon dioxide (CO2) offers a number of benefits over strong acids. Not only is it less hazardous and thus more operator friendly, it also outperforms acids in stabilizing the pH. In addition it can prevent dissolution of calcium carbonate and improve paper machine runnability. Neutral conversions using CO2 for pH control are typically more successful than alum and/or strong acids.

Reliability with ADALKA Process Stabilizer

This tool uses a combination of CO2 and sodium hydroxide (NaOH) to stabilize the papermaking process. ADALK™ process stabilizer can be used to gently increase and stabilize the pH of acidic pulps. Higher alkalinity can prevent dissolution of CaCO3 and therefore reduce the process water hardness. Common benefits are improved runnability, less foaming, fewer deposits, spots and holes, improved chemical performance and reduced felt filling.

Any questions?

One of our experts would be delighted to discuss how we can help you make your pulp and papermaking processes cleaner and more efficient

Contact us